Introduction: This blog is intended to provide information to persons in the live event industry to enhance their technical knowledge and provide a better understanding relating to many electrical aspects of equipment, wiring, and safety.

Disclaimer: Although the vast majority of the information provided is indisputable, there are cases where some of the information is open to interpretation, especially in the area of the National Electrical Code (NEC). In such cases, the “final say” is up to the local Authority Having Jurisdiction (AHJ) usually the electrical inspector. Some of the information provided herein is based on the National Electrical Code (NEC). However, NEC requirements may be accepted as written or may be modified by local authorities (by local law), especially in large cities. This column does not necessarily represent the opinion of the editorial board or Motion Labs and its owners.

Absolutely the Wrong Way of Grounding

I was scanning the web when I came across a picture depicting “the right way” to ground a generator. The writer of the post claimed he had ground a portable generator by connecting a wire from the generator’s frame to a two-foot piece of steel rod stuck in a bucket of dirt. Now, it is hard for me to believe a person with this comprehension of electrical grounding would be put in charge of equipment in a manufacturing plant. I chalked the photo up to clickbait and moved on. However, the post not only got me thinking about ground rods but also served as a reminder not to believe everything that you read on the internet, especially when it comes to your electrical installations. It’s always a good idea to check the validity and credentials of the source. If the information is wrong, it could be dangerous, even deadly as in this case.

Ground rods may be a mystery to some, but I am here to explain the magic away. Firstly, ground rods are just one form of establishing a direct connection to the earth or ground. This conductive object is often referred to as a grounding electrode. There are several other types, which include:

- Metal underground water pipe

- Metal frame of a building structure

- Concrete encased electrode (steel reinforcing rods, also termed “Ufer ground”)

- Ground rings

- Plate electrodes

I’m not going into much detail on the installation of grounding electrodes since that’s the job of the electrical contractor. You just need to know what they are and what they do, and more importantly what they don’t do. The grounding system, in which grounding electrodes are a part, is covered in the NEC, Article 250. The NEC doesn’t go into detail about why a grounding system is important, it just explains how to do a proper installation. NEC Article 250 is one of the largest chapters in the code. It’s a bit complicated and can be difficult to understand. I’m not going to try to explain it —instead, I want to give you a basic understanding of the function of ground rods.

Grounding electrodes serve basically two purposes:

- Provide a path for lightning.

- Aid in establishing an equipotential ground plane. Equipotential ground planes generally apply to high voltage utility distribution and agricultural installations where circulating ground currents have a deleterious effect on animals. This article will not cover this type of system.

It is important to keep in mind that grounding electrodes do not provide an effective path for ground faults (short circuits), nor do they provide a low impedance current path to trip circuit breakers or other overload protective devices. Earth is a poor conductor. Therefore, attempting to use it for a ground fault path will most likely fail.

To discuss grounding electrodes, let’s first look at some terminology used by the NEC. This is where a lot of people get confused, and rightly so. Even the experts responsible for updating the code sometimes struggle as they try to clarify terminology. It is interesting to look at terminology with each update to the NEC, which is revised every three years. The definitions below are excerpts from two different editions: the 2005 version and the 2020 version.

Definitions from the NEC, Article 100:

2005 — Ground: A conduction connection, whether intentional or accidental, between an electrical circuit or equipment and the earth or some conducting body that serves in place of the earth.

2020 — Ground: The earth.

2005 — Grounded: Connected to earth or some conducting body that serves in place of earth.

2020 — Grounded: Connected to ground or to a conductive body that extends the ground connection.

2005 — Grounding Electrode: A device that establishes an electrical connection to the earth.

2020 — Grounding Electrode: A conducting object through which a direct connection to earth is established.

To confuse matters more there are also alternate meanings of the word ground. For example, motor vehicles and airplanes have grounds; however, they are certainly not connected to the earth. This also applies to some low voltage power supplies and automotive circuits where the return current flows back to the source and is not necessarily connected to ground; it’s called ground, but it’s not earth ground.

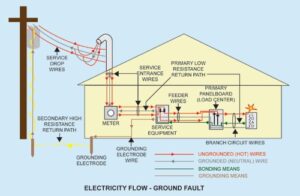

In standard electrical systems, like the one in your house, the reference to ground has little to do with the actual connection to the earth. The function of the ground, in this case, is to provide a low impedance path for ground faults (short circuits). This ground path permits the functionality of overload devices like circuit breakers and fuses when a ground fault is encountered. For all practical purposes, none of the ground fault current will go to earth, instead, it will try to return to its source. The source of electricity for your home is the transformer on the utility pole. Because the in-house circuit breaker is in series with the transformer, it will trip and not allow sustained high currents to damage the transformer or the associated wiring.

Most utility poles that support transformers have ground rods connected to the utility neutral. Your house also has a grounding electrode. However, the impedance of the soil from the house to the pole is too great to provide an adequate path for significant current flow. This high impedance soil path is too high to trip a 15- or 20-amp circuit breaker.

As we mentioned previously, the major reason for grounding electrodes is to provide a safe path for lightning. What we’re trying to do with a grounding electrode system is to route the lightning directly to the earth, rather than through your house. Most of the time it works, but you can’t control Mother Nature. Lightning is extremely unpredictable; we can only hope it picks the path we have provided with the grounding rods.

Lightning is a form of static electricity. Lightning does not behave in the same way as current flow in a standard circuit, which requires a source, a load, and conductors (wires) from the source, through the load, and back to the source. The term “static” refers to the buildup of electrons (typically in the clouds) until the difference in potential from the clouds to the earth becomes of such a magnitude that the built-up charge seeks equilibrium. At the point of discharge, the electrons are no longer static.

Unlike a typical hardwired circuit, lightning will seek a discharge point (on the earth) that is available to dissipate static electricity. There is no specific predetermined voltage that is required for discharge. It can depend on many other factors including but not limited to the height of an object, the conductivity of an object or the difference between abundance and deficiency of electrons in a particular area. Grounding electrodes (ground rods) offer some protection by providing a more direct path in the event of a lightning strike on utility wires and poles, or a direct strike on buildings and other structures. The typical ground rod length is 8 ft. In some cases, a second ground rod may be installed where the soil is relatively non-conductive (dry or sand). Engineering evaluations have determined that installing more than two ground rods has little or no benefit.

A comprehensive explanation of the causes and effects of lightning can be found on the National Oceanic and Atmospheric Administration (NOAA) page linked below:

http://www.nssl.noaa.gov/education/svrwx101/lightning/faq/

Live Entertainment and Grounding Rods

Now, how do grounding rods relate to live entertainment systems?

I can think of a couple of scenarios where this information may be helpful: generator power and the grounding of outdoor metal stage and canopy assemblies.

In most cases you won’t have to worry about temporary generator hookups, which are usually done by professional companies and are most likely approved by the local electrical inspector. Generators for shows, that you will most likely encounter, are covered in NEC 2020, Article 702 — Optional Standby Systems. According to Article 702.11 Portable Generator Grounding. Generators require grounding electrodes. This can be accomplished in one of two ways:

- If the generator is not connected in any way to the normal building electrical system or where the grounding electrode system conductor is opened by a transfer switch, a grounding electrode must be installed.

- If the generator power is fed to the load via a transfer switch that only transfers the line conductors but not the conductor path to the building’s existing grounding electrode system, then you need only connect the generator grounding conductor to a grounding electrode terminal of the building. The exact connection point is not specified.

The above wording is paraphrased from the code and not verbatim. If you’re involved in this type of work, refer to the code section in its entirety.

There is an exemption concerning the requirement for grounding electrodes on portable generators: refer to NEC 2020, Article 250.34 Generators-Portable and Vehicle-Mounted:

- Portable Generators. The frame of a portable generator is not required to be grounded to the earth if:

- The generator only supplies equipment or cord-and-plug-connected equipment through receptacles mounted on the generator, and

- The metal parts of the generator and the grounding terminals of the receptacles are bonded to the generator frame.

- Vehicle-mounted Generators. The frame of a vehicle mounted generator is not required to be grounded to the earth if:

- The generator frame is bonded to the vehicle frame.

- The generator only supplies equipment or cord-and-plug-connected equipment through receptacles mounted on the generator, and

- The metal parts of the generator and the grounding terminals of the receptacles are bonded to the generator frame.

Important Note: These types of generators must have the neutral and ground bonded together. Otherwise, any ground fault will not trip the circuit breaker. This only applies to generators that are stand-alone and not connected to an existing building where a neutral/ground bond is already established and is not interrupted by a transfer switch.

As far as the grounding of outdoor staging and canopies is concerned, it’s not covered directly in the NEC. However, code Article 525 Carnivals, Circuses, Fairs and Similar Events may apply: it’s up to your local Authority Having Jurisdiction, usually the electrical inspector.

Article 525.30(3) states (in part): The following equipment connected to the same source shall be bonded: metal frames and metal parts of portable structures.

Bonding is defined as: Connected to establish electrical continuity and conductivity. So, under this article, metal stages should be grounded. But remember this does not necessarily mean that you need a grounding electrode (ground rod). It just requires that the stage needs to be connected to the grounding system that feeds the power to the stage. If, however, the AHJ (usually the electrical inspector) considers the stage or the canopy a “structure”, then NEC, Article 250.32 would apply. This article requires a grounding electrode for structures. Even if it’s not required, it’s probably a good idea to install one anyway, especially if the stage is in the middle of a field.

Grounding the metal stage structure (to earth via a ground rod) may mitigate the damage from a lightning strike. It’s better for the lightning to travel from the structure directly into the ground via the electrode, rather than through the stage equipment to the earth. But remember there are no guarantees regarding lightning. Earth grounded metal structures (via a ground rod) neither attract nor repel lightning. However, a properly grounded/bonded structure may provide a safer (more direct) path to ground during a lightning strike.

The code requires that if an auxiliary grounding electrode is installed, it must also be connected (bonded) to the grounding terminal of the power system that provides power to the stage. Auxiliary grounding electrodes are in addition to the main grounding electrode system at the electrical service entrance where the main bonding jumper connects (bonds) the grounded conductor (neutral) to the main grounding electrode(s). In this case, there must not be a local direct connection of the neutral to the auxiliary grounding electrode. This assures that there is no voltage difference between the equipment and the structure. In addition, ALL grounding electrodes on the electrical system must be bonded together. An accepted method of providing continuity between the main grounding electrode system at the service entrance and any auxiliary grounding electrode, which in this case is the ground rod near the temporary stage, is via the equipment grounding conductor in the stage power distribution system. Remember this is connected to the main electrode system of the electrical service via the feeder circuit grounding conductor; refer to NEC 2020, Article 250.54.

Basically, what we’re trying to do is have all grounds bonded together at the same potential (equipotential). Whether it be feeder grounds, structure grounds, equipment grounds, electrodes, etc. Remember voltage is a difference in electrical potential. If everything is bonded together, there is no voltage, and hence no amperage, among these parts. This will also reduce the possibility of ground loops, which may cause a “buzz” in the sound system.

I was on stage once holding a guitar and received a small shock when my lips touched the mic. That was caused by a difference in potential between the mic and the shield on a guitar cable. Had the guitar cable been properly grounded through the amplifier as well as the mic, there would have been no potential difference and I would not have been shocked. The shock I received could have been much worse had there been no primary ground at all. Performers have been electrocuted on stage because of improper grounding. Proper grounding not only saves equipment but saves lives.

The opinion expressed herein is only a personal interpretation. Check with your local authorities for final decisions on code matters. If you’re not absolutely sure of what you’re doing, consult a professional.

Motion Labs is here to help.

We encourage you to ask questions, provide constructive criticism, and suggest subjects for future blogs.

Remember some of the subject matter may be argumentative in nature. If you disagree or need clarification, let us know.

Thanks:

Jim Herrick

About the author:

Jim Herrick has over 40 years’ experience in the electrical field. Licensed in the State of New Jersey as an Electrical Contractor (License #6748) and Electrical Inspector (License #7702). Of the 40 years’ experience, 30 included work in the theatrical industry, which also included electrical equipment design for major companies in the industry.

Leave a Reply